Fachgebiet Struktur und Eigenschaften von Materialien

Standort an der Technischen Universität Berlin

Standort am Helmholtz-Zentrum Berlin

Kontakt

Fachgebiet für Struktur und Eigenschaften der Materialien

| Einrichtung | Struktur und Eigenschaften der Materialien |

|---|---|

| Sekretariat | EW 2-3 |

| Gebäude | KPK |

| Raum | 001-015 |

| Adresse | Hardenbergstraße 36 10623 Berlin |

| Termine | nach Absprache |

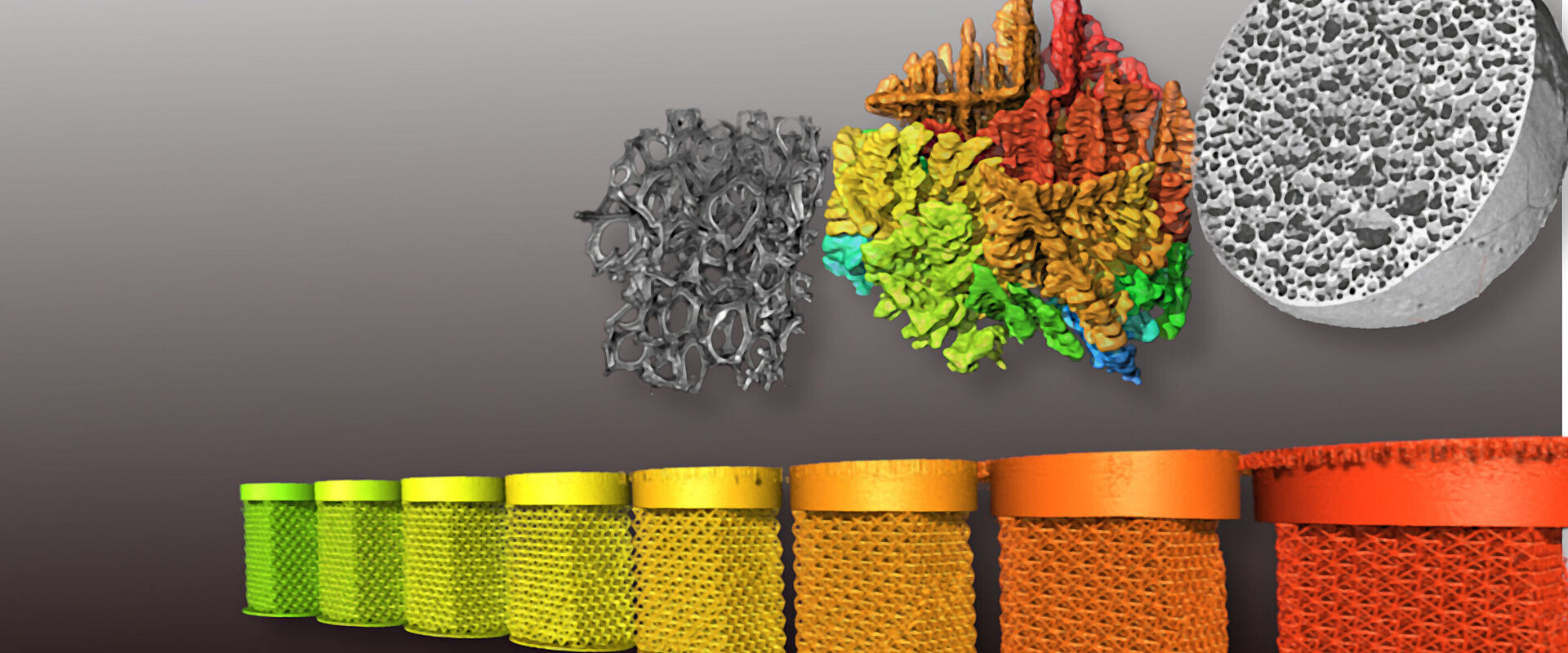

© Oana Popa-Costea

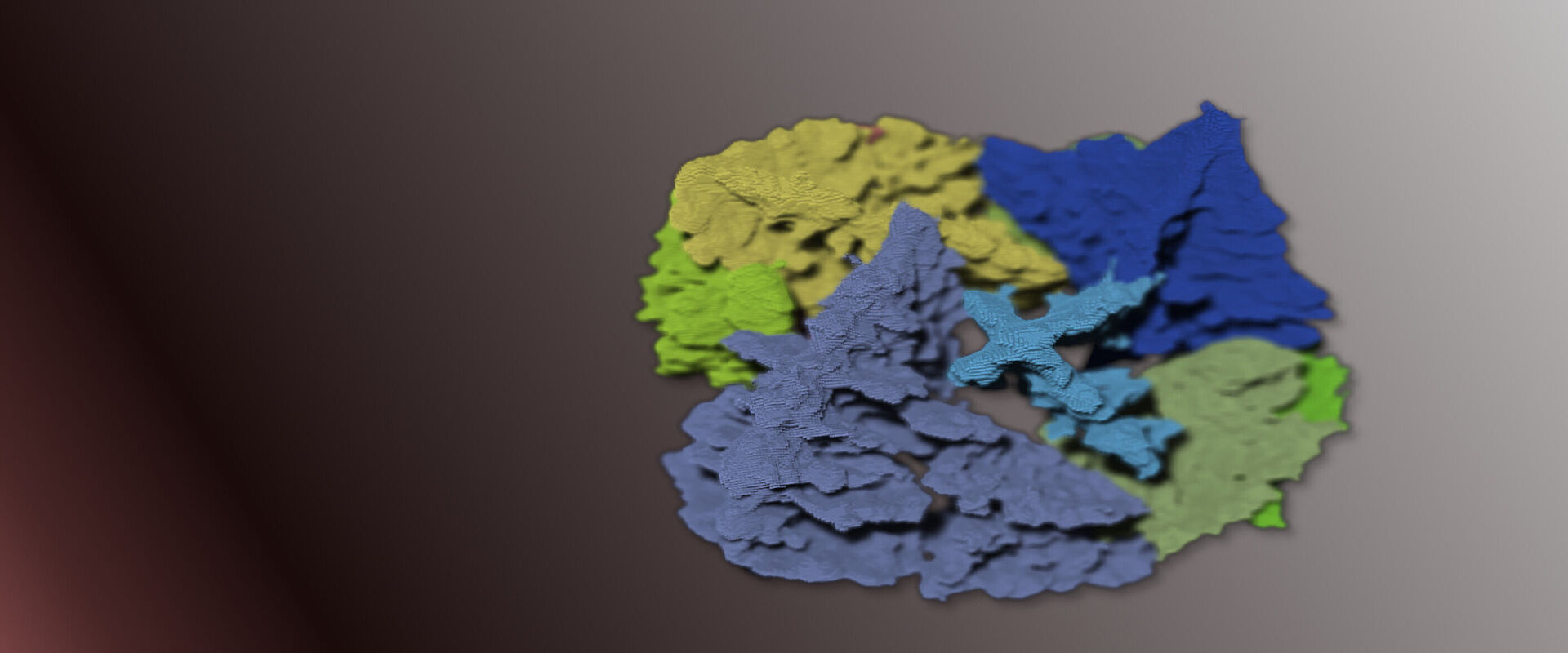

© Oana Popa-Costea